What Grit Sandpaper Should Be Used for Automotive Paint?

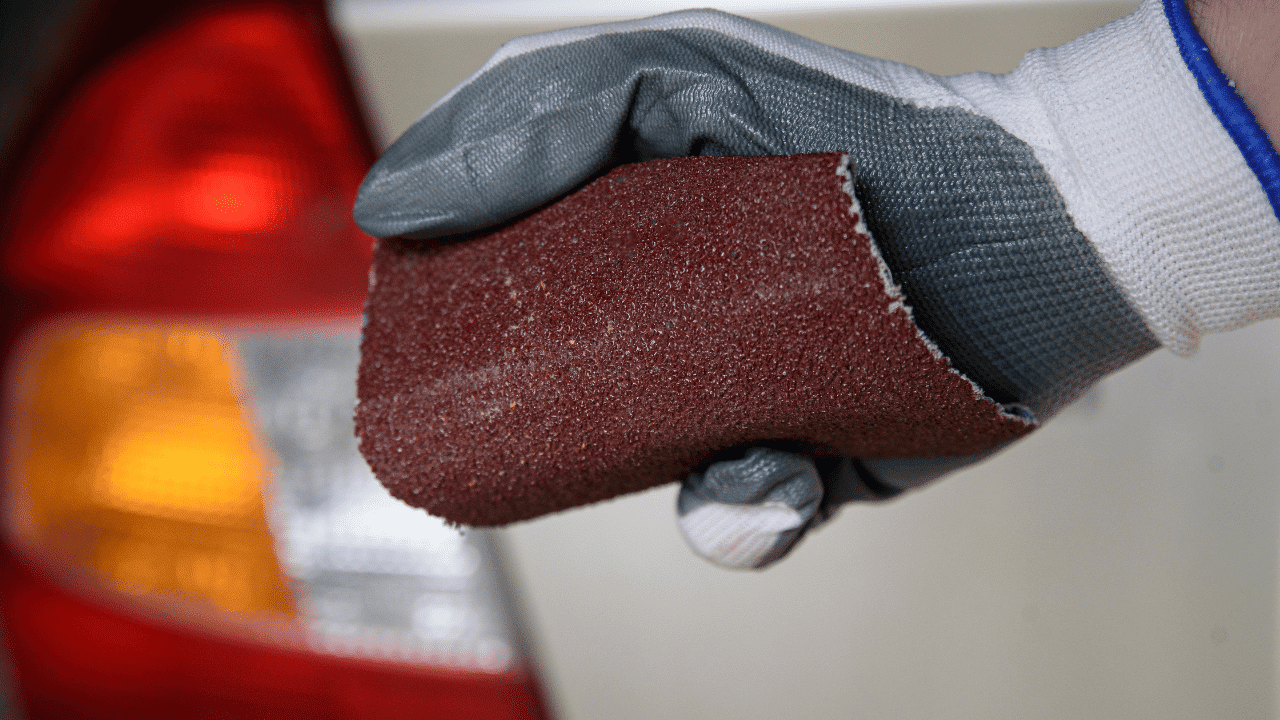

Professional bodyworkers use various grits of sandpaper during bodywork projects. Choosing the right sandpaper grit for the job is critical.

Grit refers to the number of abrasive particles per square inch on the paper. Lower numbers indicate coarser sandpaper. Higher numbers indicate finer sandpaper.

24 to 36-Grit

Choosing the right type of sandpaper for your sanding application is key to completing the job successfully. Whether you’re working with wood or metal, knowing what each grit does helps you choose the best option for your project.

Generally speaking, sandpaper in the 24 to 36-grit range is best used for automotive projects where rough edges have formed along a panel. You’ll want to use this grit when you have rough dents or scratches on the vehicle that need to be flattened out before a new coat of paint can be applied.

This grit is also helpful for vehicles with light corrosion around the edges that need to be removed before a new coat of paint can be added. It’s also a good choice for removing light scratches that have been left behind by previous paint jobs.

The sandpaper grit size is determined by how many particles of the abrasive material fit through a standard filtering screen. Grit numbers are regulated by the Coated Abrasive Manufacturers Institute (CAMI) and the Federation of European Producers of Abrasives (FEPA).

Sandpaper grits are available in a variety of forms, including sheets, belts and discs. Sheets are designed for hand-sanding applications, while belts and disks are used with power sanders like orbital or drum sanders.

40-Grit

When sanding automobile paint, it’s important to choose the correct grit sandpaper. Sandpaper is rated numerically with lower numbers indicating coarser grits. This helps you identify which grit is right for each stage of your painting project.

For example, a coarser grit is appropriate for heavy sanding and stripping, while a finer grit is suitable for smoothing surfaces and removing small imperfections. You can use these grits in stages, starting with the lowest grade and working your way up to the finer ones as you proceed.

Coarse grit is usually applied to auto panels that require a lot of sanding, such as the hood, roof and doors of cars and vans. It can be used to remove rust spots, scratches and other surface defects. However, it should be used only after gentler sanding with higher-grit sandpaper.

Professionals also use 40-grit sandpaper to prepare for a refinishing job. This grit can help reduce the risk of damage by eliminating small imperfections, such as orange peel or stains.

In addition, it can be used to rejuvenate older paint jobs by removing the scuffs and marks left behind by previous paint jobs. It’s also great for cleaning up areas of the vehicle that have been damaged, such as passenger doors or roofs that run out of paint.

50-Grit

If you’re looking to sand the paint on a vehicle, then it’s important to choose the right grit sandpaper. This is the sandpaper that will remove any flaws in the surface of the car’s exterior and help the vehicle’s paint flow smoothly and evenly.

A 50-grit sandpaper is one of the coarser choices and is designed to get rid of any imperfections that might be present on the vehicle’s surface. It’s also ideal for removing any rust spots that are present on the vehicle’s body.

Professionals use this grit to remove light clear coat scratches and other small, obvious flaws in the surface of the vehicle’s paint. It’s not a good choice for large or pronounced clear coat scratches, though.

It’s also used to remove any rust spots that are present on the car’s exterior and help the body’s paint flow smoothly and evenly. Rust is cancerous to metal surfaces, and it can lead to holes in the body of a vehicle if not treated quickly.

It’s also a great option for sanding old body filler and shaping new body filler for high areas on the body of the vehicle. It’s also excellent for removing heavy rust and cleaning the rusted metal down to shiny, clean metal.

60-Grit

If you want to repair a damaged car’s surface, you’ll need the right sandpaper. Whether the damage is caused by a collision or a sloppy paint job, the wrong grit can leave scratches or make your repair worse.

To avoid this, sandpaper professionals use a variety of grits for different jobs. Each grit type is designed to smooth surfaces and remove imperfections before a coat of paint is applied.

A coarse grit will sand down material quickly, while finer grits smooth out painted or bare wood surfaces and are used to remove old varnish or polyurethane. Coarse grit is also used to remove heavy gouges and to get into corners and crevices on objects like cabinets and drawers.

When sanding wood with a sander, it’s always best to wet the surface. This will help to prevent raised grain and allow the sandpaper to work more efficiently.

Professionals also often wet sand metal surfaces to ensure they come out as smooth as possible. This is especially useful when sanding with high grits, like 1500 and beyond.

Professionals also recommend starting with a coarse grit and moving up to the finer grits as needed. This allows you to eliminate any previous scratch marks that may be present on the vehicle.

80-Grit

When it comes to sanding and painting, the right type of grit sandpaper is important. Choosing the right grit is critical to achieving the smooth, glossy finish you want.

Typically, you’ll start with coarser sandpaper and then switch to finer grits as the surface becomes smoother. This step-by-step process consists of scratching the surface with progressively finer abrasives, abrading away the marks left by the coarser sandpaper to create a smooth surface.

Professional sandpaper manufacturers use a system of grit numbers to describe the abrasive particles that are embedded in each sheet of sandpaper. These numbers are based on the number of holes per square inch that were used in the screens that sieved the abrasive grains during the sandpaper’s manufacture.

For example, 60-grit sandpaper uses abrasives that are larger than those found in 80-grit paper. This makes it more effective at removing stock faster and with less effort than 80-grit paper.

In contrast, 120-grit sandpaper has a more uniform grain and is softer, meaning it leaves finer sanding marks on painted surfaces. This is especially helpful for feathering or rounding corners and sharp edges.

In addition to the abrasive particles embedded in each sandpaper, the grit number also reflects the micron size of the particles. In most cases, these microns are derived from the United States CAMI (Coated Abrasive Manufacturers Institute) and European FEPA (Federation of European Producers of Abrasives) “P” grades, which were developed to help auto-body refinishers determine grit size.

100-Grit

There are a lot of different grits of sandpaper available, so choosing the right one is important. The grit of the sandpaper is a measure of its coarseness, determined by the size of the abrasive particles on its surface. The grit of the sandpaper ranges from fine enough to resemble cooking flour all the way up to larger particles that look like granulated sugar.

Grit sizing is regulated by the Coated Abrasive Manufacturers Institute (CAMI) and the Federation of European Producers of Abrasives (FEPA). This is done to ensure that each type of abrasive is sized properly so it will perform its intended function effectively.

The grit on a piece of sandpaper is measured by how many of the particles on the abrasive surface fit through a filter, which is typically 1 square inch. Larger particles will fit through a larger screen, while smaller particles will fit through a smaller screen.

This process can be a little confusing at first, but once you understand how the grit of a piece of sandpaper works, it’ll be easy to choose the right grit for your next sanding project. A good grit sequence is one that eliminates stock and finishes before switching to successively finer grits that remove sanding marks until you get to smoothness.

The grit of a piece of abrasive is important to consider when sanding a vehicle’s paint, especially before applying a new coat of color. It can also be useful for removing light corrosion along the edges of doors and other panels.