Understanding the Auto Transfer Case Process

The concept of the auto transfer case is not new but also not many people are aware that remanufactured auto parts can also be transferred. The process of remanufactured transfer cases is quite hassle-free. It comes with quite many advantages which is why cracking this deal is not a bad idea. The cores of the transfer case are usually tested during the process of manufacturing itself. The best part is some top-notch quality cores can be re-manufactured. Some pieces are even subject to getting damaged but also replaced with new ones. The 241DHD transfer case is one fine example of such a case that undergoes a reliable process

The process involved

In the whole manufacturing process, before even the product is out for purchase, there is already a process involved such as:

-

Disassembly

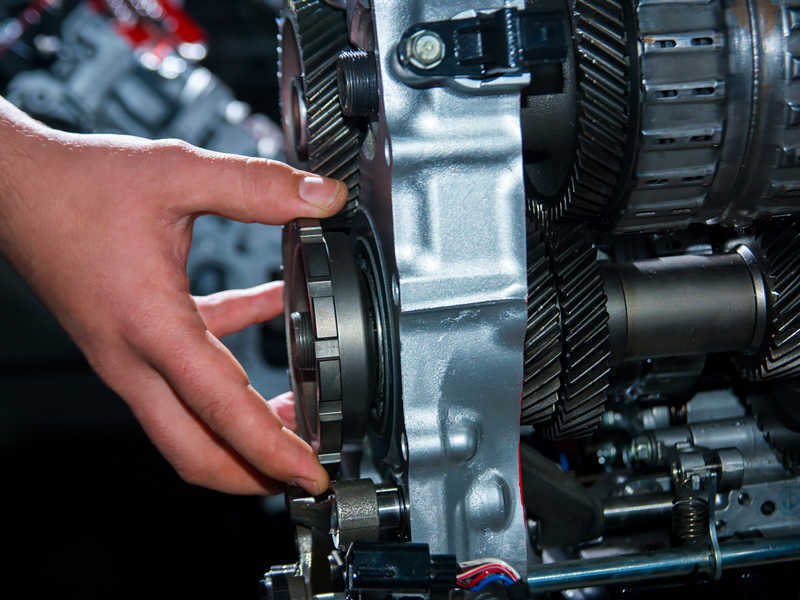

When the used transfer case comes to the re-manufacturing facility, it is then counted as entirely disassembled. The components are correct and present then.

-

Cleaning

Once all the internal components from catalogs and the gaskets are discarded, the shaft, case, and gears will be washed under the washer with high pressure.

-

Examination

For better remanufactured transfer cases, the next step will be to examine the parts. For this, all pieces will be inspected to see if there is any defect for which the gunk will be first removed and the inspection will be carried out. The parts that will not clear the musts will be machined for repairs or can be replaced too.

-

Parts Replacement and Re-Assembly

Along with rings and joints, the components may not meet all the requirements and specifications. That is when they shall be replaced in the assembly. The replacement and inspection of the electrical part that includes the control unit and solenoids will be right done.

-

Checks

Once the whole assembly is done, every transmission case that will be re-assembled can be placed on the machine. There could be certain stimulations that will further be carried out for operation testing and transmission case quality assessment.

Benefits of Remanufactured Transfer Cases

-

Done at Factory Setting

The best part of remanufactured transfer cases is that it is created in the assembly line of the factory. The technicians can also specialize in certain areas whole very transfer case shall have some quality testing done.

-

Replaces Parts

With such an option, there will be a disassembly done thoroughly; cleaning done well and surfaces can be machined to meet the factory specification while the parts will be better updated.

Conclusion

In the industrial process of re-manufacturing, the returns can be utilized well while the uncooperative aspects can be made into better condition to be more productive. Since the whole process is done from the scratch, the risk of any failure is likely to be less. Besides, the result will be a finished product that shall be identical to the new one. Certainly, it is a great deal to crack as it offers all kinds of processes to be done systematically.